Thermal Imaging HVAC Inspection and Service

Thermal imaging cameras are a very powerful tool for use during HVAC inspections and services. These tools allow technicians to quickly diagnose and monitor potential problems with the HVAC equipment itself, locate air leaks in the building envelope, water leaks, electrical problems, and more. Identifying and correcting these problems early can lead to less costly emergency repairs, reduced/planned equipment downtime, and optimum unit performance.

What is Infrared light?

“Infrared is in the range of the electromagnetic spectrum between microwaves and visible light. Infrared has a frequency from approximately 30 THz up to about 400 THz, IR light is invisible to human eyes, but we can feel it as heat if the intensity is sufficient” - What is Electromagnetic Radiation. According to NASA, our eyes are only able to detect the wavelengths in the 380 to 700-nanometer range, known as the visible light spectrum. Technically all forms of electromagnetic radiation are forms of light, and the visible light spectrum makes up only a small portion of the 7 different types. Infrared wavelengths are longer than the wavelengths emitted by visible light, which is why we are unable to see them, but tools such as a thermal imaging camera can sense these invisible IR wavelengths and convert them to a digital thermal image that allows us to “see” them.

Image credit: Biro Emoke Shutterstock

“With thermal imaging, the portion of the spectrum we perceive is dramatically expanded, helping us "see" and "measure" thermal energy emitted from an object. Unlike visible light, in the infrared world, everything with a temperature above absolute zero emits heat. Even very cold objects, like ice cubes, emit infrared. And visible light doesn't affect the thermal world, so you can see equally well in highly lit and completely dark environments.” - ( FLIR.com ) Temperature and IR radiation are directly connected. The higher the temperature of an object, the more infrared radiation will be emitted.

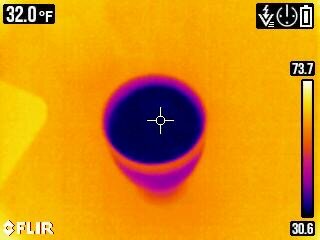

Ice water with a FLIR thermal Camera

Using Thermal Imaging for HVAC Work

In the not so distant past, thermal imaging tools were extremely expensive and out of reach for most of us as a diagnostic tool. As technology advances and improves, these tools have become much more affordable, and are now an accessible option for the masses. Options include stand-alone thermal cameras, multi-meters with integrated thermal imaging, or you can even grab a small compact attachment that plugs into your smartphone.

Here are a few great options to help get you started in thermal imaging.

HVAC systems can be extremely complex and require proper maintenance to ensure optimal efficiency and performance. Air leaks, improperly installed ductwork, failed electrical components, moisture, refrigeration related problems and more can all lead to costly repairs, increased energy costs, water damage, and poor indoor air quality. Some of these issues can be extremely difficult to find without proper tooling. Using a thermal imaging camera, HVAC technicians can quickly and efficiently spot many of these problems with a glance. Since many of these issues are not readily visible, they often can be easily overlooked, allowing the problem to manifest into a much larger and costly repair down the road. It is important to find and correct these issues with the heating and cooling system as quickly as possible. Using a thermal imaging device can help you find these faults and then take the proper course of action to correct the issue.

Air Leaks and Locating Duct Work

As you can see from the photo, using a thermal imaging camera you can easily locate the ductwork in a building behind sheetrocked walls. This photo was taken in my bathroom at my own home. Using this camera, I was able to discover that when my house was built, the flooring contractor covered up the vent hole and duct. Unfortunately, I can not locate the original photo where my entire bathroom floor was glowing pink, and I knew something was wrong. This photo was taken after I cut out the floor opening and added a vent, but you can clearly see the other ducts supplying warm air to the upstairs rooms.

Another great use for this thermal camera is locating duct leaks or blockage. If there had been a hole in one of these ducts allowing warm air to escape into the wall, a much larger portion of the drywall would be indicating a heat signature. Conversely, if the duct was partially blocked with a fire damper, garbage, or animal, you would likely see the restriction as the duct being cooler immediately after the blockage. Falling insulation poorly installed insulation and air gaps in the building envelope all lead to increased operating costs and wasted energy. Insulation gaps failed weather stripping, faulty window seals can happen to any building over time which causes drafts in the conditioned space. These problems can be difficult to pinpoint, but with the help of thermal imaging, it becomes much easier. Sometimes visualizing these leaks, even with a thermal camera, can be difficult and can require precise building air pressure testing and temperature control.

Water Leaks and Moisture

Water leaks and moisture can often be one of the most difficult to find and most troubling problems within a building. Often, these leaks are not located until its too late. If left, the damage can become compounded by leading to mold growth, structural damage, foul odor, and a generally poor indoor air quality.

How can a thermal camera help locate moisture? As water evaporates, heat is absorbed with it, which causes the wet areas to appear cooler in the thermal images. Slight moisture tends to only cause very minimal heat differences, so a high quality, sensitive thermal imager should be used to reliably locate moisture.

HVAC systems often use water as a means of transporting heat in commercial buildings. (Chillers, Boilers, Hydronic heat pumps, and more) Additionally, condensation is a byproduct of evaporative cooling. (all HVAC equipment using refrigerant or chilled water will generate condensation in the right conditions) Condensate drain lines can become plugged allowing the water to overflow above ceiling tiles, in attics, mechanical rooms, or wherever the HVAC system is located. Water leaks can happen anywhere, causes ranging from a faulty valve, a deteriorating pipe, an old worn gasket, or a sheetrock screw ran through a plumbing fixture. No matter the cause, its important to identify the problem and correct it before it gets worse.

I have also seen a run of underground heating loop water lines develop a leak. Using a thermal camera, we were able to narrow down the approximate location to begin digging in search of the source. Without that tool, I would have been guessing where to start digging, and probably would have ended up digging a lot more ground to find and repair that leak.

General HVAC Equipment Inspections

HVAC equipment encompasses a wide array of equipment types. Boilers, chillers, air handlers, compressors, and more. All of these pieces of equipment use a mixture of electrical control, refrigeration components, and mechanical moving parts to perform their function. These systems must be maintained regularly to avoid breaking down. Using Thermal Imaging for HVAC inspections may help reduce downtime and expensive repairs by finding these issues prior to failure. FLIR states that “Nearly everything that uses or transmits power gets hot before it fails” When I think about that statement, I think of car engines overheating, computers and servers hitting critical temps, bearings without proper oil/lubrication, poor/ worn electrical connections. All of these scenarios cause excessive heat build-up and ultimately lead to failure.

Looking for a comprehensive HVAC Inspection guide? Check out my linked Blog Post!

Compressor pumping refrigerant. You can see the suction side of the compressor is bring cool refrigerant back to the compressor in order to cool the motor wingdings, before getting compressed to a hot vapor and leaving out the discharge.

Being able to see that excessive heat building up, we can use these thermal cameras as a predictive maintenance tool. Many of these break downs can be identified and repaired before that failure happens. Quickly scanning the system we can gather a lot of information of the total system health. Restrictions in the refrigerant system such as a plugged filter drier, a stuck reversing valve, a partially plugged pass on a coil, or a compressor (like the type pictured above) not loading/unloading can all be easily spotted with a glance of a thermal camera.

Wiring to contactor overheating. Badly worn and pitted contactor surface was found to be causing the excessive heat build up.

Overheating electrical connections, breakers, switches, or overloaded circuits will all be easily spotted using a thermal camera. Seeing an overheated motor may indicate failing motor bearings, over- current or loose connections. Investigating the problem further may reveal improper belt tension, lack of grease in the bearing, or even improperly sized ducts causing the fan to over amp. During an inspection of the air handler unit (AHU) you may notice excessive heat build-up around the unit which might indicate lack of airflow such as a dirty coil, plugged filter, or cracked heat exchanger.

Equipped with a thermal imaging camera, you can quickly locate, solve, and repair deficiencies in all types of HVAC equipment. Utilizing the tool properly will ultimately save money for the equipment owner by decreasing the operating costs of the unit both inefficiencies as well as component failures.

The equipment used to capture these photos can be found here.

As an Amazon Associate HVAC Tool Review earns commission from qualifying purchases